We did a similar project to this one on a Lamborghini Huracán back in the summer of 2020. Doing that project really opened our eyes to what is possible with these V10 engines.

After experiencing the build and power of this car, it just made sense to get involved and actually have our own shop car to promote and develop this package further.

Well, I decided to go out and buy an Audi R8 V10 Plus, Standard Form. It’s all in the interests of business, I assure you. I mean, the fact that an unmodified Audi R8 goes from 0 to 60 mph in 3.4 seconds and that sitting in one feels like sitting inside the cockpit of a jet plane has nothing to do with it. Scout’s Honour.

So, anyway, back to business.

The kit

We’ve worked previously with a company in the States called 3:16 Speed. They provide readymade Twin Turbo Conversion kits for R8s as well as the Huracán. They were the guys who provided the kit for our Huracán conversion, in fact, and we were so impressed with how comprehensive the kit was that we decided to go with them again.

The readymade twin-turbo conversion kit from 3:16 Speed is made up of:

- The turbos — Precision 6466 or 6266 Mirror Image Turbos

- Precision 46mm wastegates

- Precision 50mm Blow-off valves

- Air-to-water intercoolers

- Heat exchanger

- Vibrant Vanjen Assemblies — on all charge pipe connections

- Oil and coolant XRP crimp hoses

- Front trunk water tank for air-to-water system

- Factory exit stainless steel exhaust

- K&N Air Filters

- All other necessary hardware for install

The other part highly recommended for this conversion was the ECU.

Technically, it is possible to run this kind of conversion on a standard ECU. But, to get maximum control over the car as well as to ensure engine safety, it makes sense to use a standalone Engine Management System.

We went with a company called Syvecs which is a UK-based premium-brand ECU manufacturer. We’ve worked with the guys from Syvecs on plenty of other projects before. Good guys with exceptional customer service. Excellent ECUs.

It also lets guys like us at Auto Torque do awesome things like convert R8s into Twin Turbos!

The ECU is critical. It’s one thing to put two big turbos on a car but muscle is nothing without brains.

Each of these two items — the turbo kit and the ECU — had a six-week lead time so you can imagine our restlessness as we waited eagerly for these babies to arrive so we could get started!

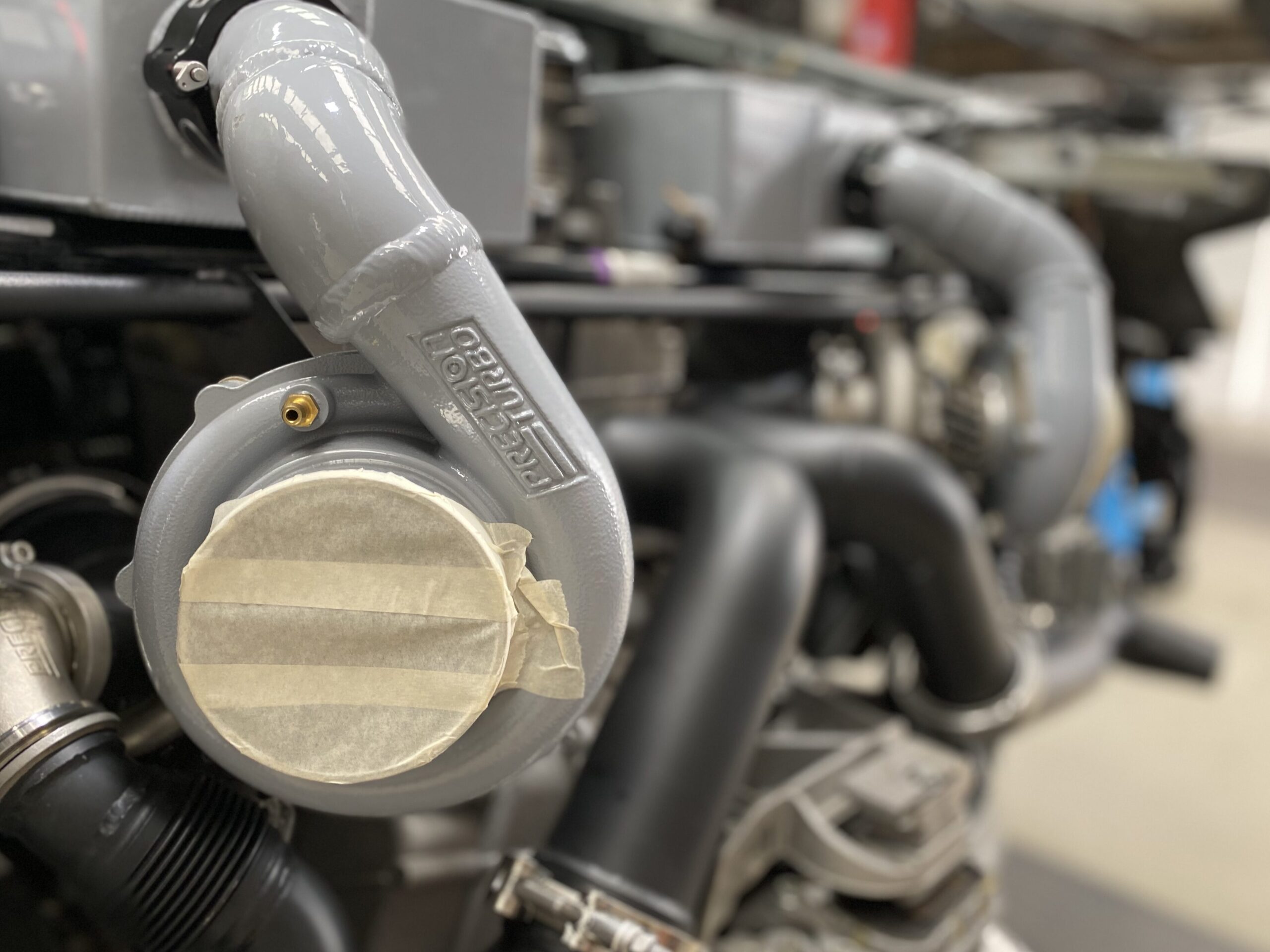

The Turbos

The kit from 3:16 came with two Gen2 turbos from Precision — the larger 6466 versions we opted for.

The 6466 is a bigger turbo than the 6266, so guess which one we went with.

The 6466 is good for about 1,200 to 1,400 WHP with the right fuel system. Yeah, we were pretty excited as well!

The Gen2 is the latest version from Precision with better cooling and different blades inside the compressor housing. It is an absolute masterpiece of turbo engineering with its compressor wheel forged from Aluminium Alloy 2618A, which is the same material typically used for aerospace and defence components.

Did you get that? Aerospace.

Yes, that’s the turbos we use for our conversions.

For the uninitiated…

If you’re keen on turning your car into a space rocket (who isn’t?) but are confused at how turbos work as well as all the many terms that are used, this video can help.

But you don’t need to understand about wastegates and intercoolers (which we also call a charge cooler), blow-off valves and all of that stuff. We need to know about that stuff. All you need to know is where we’re located. (We’re here, by the way.)

You have to keep it cool. You want to put as much cold air through these turbos and into the engine as possible. To achieve this, a water tank is installed at the front of the car and it circulates water around the intercooler/charge cooler to cool the air down. That’s a pretty basic explanation of it. But unless you’re planning on coming to work at Auto Torque, it’s all you really need to know. We’ll take care of the rest!

One-week installation

Once we got the kit from 3:16 and the ECU from Syvecs, we set aside a week for our technician to do the installation.

That’s generally the time it takes to complete one of these — one whole week to fit the kit and do all the plumbing. And then it’s a case of tuning it.

Even so, we had to put in a lot of bleary-eyed late nights because we were determined to get the kit fitted and singing before the next VMAX200 on 16 September where we were hoping to show off — ahem, display — our masterpiece to fellow supercar enthusiasts, and hopefully also turn a few heads.

All in all, we sweated for two weeks — doing the install itself and then mapping it — to get this thing done. If you can imagine your favourite sports car movie where everything comes together in the last minute — well, that was us. Because we installed the base map on the Friday night before the VMAX200 event on the Saturday morning!

We wouldn’t have done it any different.

The install itself took a week, as expected. And the second week was dedicated to fine-tuning the fuel, the boost and the ignition-timing to get as much power out of it as we can.

As a side note, the map was developed by Romain from Race Cal Ltd, one of the best ECU mappers in the world. He helped us one late night, and we were truly grateful for his input.

Made for road-fuel — everyday vehicle and a track vehicle at 850 HP!

Our goal, from the start, was to run this car on standard road fuel, the kind you can get at the pump at any gas station on the road such as Shell V-Power which, is a 98 RON fuel.

Our primary objective was to make this a road-going package so we could use it for everyday driving, but also if you wanted to go down on a race strip or do a track day, then you can and still have plenty of power on tap.

I’m glad to say that we achieved that objective.

Calibrating it for road-fuel we aimed to get 0.5 bar of boost which equates to an impressive 850 HP delivery!

For the record, 850 HP is a staggering number for such low boost and using plain old road fuel. (and, if you’re thinking of converting your everyday commute-vehicle to this rocket ship, then you’re absolutely right for doing so!)

VMAX — September 2020

For those of you who have never been to VMAX (shame on you!), it’s a high-speed event where supercars and hypercars get to flex their muscles on a 1.2-mile stretch of runway, and show off their top speeds.

There is no better thrill, let me tell you.

To say we were apprehensive is an understatement because we hadn’t actually run the car at full speed yet!

We knew the car was safe and doing what it was supposed to do, but we hadn’t actually pressed the beast to its limit.

Romain came with us to VMAX, on standby for any additional tweaks to the map.

Unfortunately, we had been supplied the wrong transmission-control map (gearbox map) which sadly led to a small amount of clutch-slip and didn’t allow us to take the V10 up to its maximum potential. The clutch slip limited the V10’s ability to go full-throttle in 5th, 6th and 7th gear.

Still, despite this small fallback, the event allowed us to tune the car and get the engine running healthily and happily

Post-event fine-tuning — 200+ mph goal

We sorted the TCM (Transmission Control Map) after the VMAX event. Again, thanks to Romain from Race Cal. He had just developed a map for the transmission control and sent it to us.

The new TCM map in the end which led to lightning-fast gear changes, delivering the right amount of clutch pressure to stop the clutch from slipping. This had the direct result of increasing the car’s output in the higher gears.

So, the next goal, of course, then became to run the vehicle at VMAX in October to see how hard we could push it.

Our goal was to break the 200 mph limit. (I did mention we were creating a rocket ship, didn’t I?)

Racing fuel and Audi R8/Lamborghini Huracán weak spot

We didn’t think we’d crack the 200 mph barrier on road fuel. So, we prepared a second map, geared for racing fuel this time.

But both the Audi R8 and the Lamborghini Huracán have a weak spot: When you push too much boost through the engine, the inlet manifold starts to leak boost.

But, hey, lack of a ship never stopped a man from sailing the ocean, did it?

To resolve this inherent weakness in the Audi R8, we replaced the standard bolts on the inlet manifold with slightly longer, special high-tensile bolts that we had experience with.

VMAX — October, 2020

We had more time to prepare for October’s VMAX than for September’s one, seeing as we weren’t working until the last minute to get the vehicle ready!

We did some limited fine-tuning on the road with racing fuel — as much as can be done on public roads (which is not much, let me tell you).

Once we got to the VMAX runway in October, we started to do some runs and logged the data in the engine ECU. To do this, it’s necessary to drive down the runway at different levels — part throttle, full throttle, different gear changes — and then log all the data in the car’s computer.

Romain was on hand again so he could tweak the Engine Map. He calibrated the ECU each time so that we could get the vehicle to maximum performance.

We managed to dial the boost up to 0.6 bar on race fuel. And, let me tell you, that car felt fast and highly capable.

Even though the increase wasn’t huge, the racing fuel made a massive difference. Just increasing it by 0.1bar livened up the car so much that it felt like an entirely different animal.

Best of all, we clocked 212 mph on the speed trap while I was personally driving it. I got it to 180 mph and then it just lifted off. We got a feel for its speed, kept it there for about five seconds, not flat-out yet. I saw the finish line, held it flat, went into 6th gear then 7th gear and hit that speed trap at 212 mph.

The car is actually capable of more. We could’ve hit the limiter at 220 mph but we would’ve done so way before the end of the runway which would not have been good mechanical sympathy for the car. We wanted to reserve the engine and be sensible with it because it was still very fresh and very new.

We did a few more half-mile runs after that just to do some more fine-tuning and testing. But we found that we had actually reached the maximum capacity of the fuel system. It was impossible to put any more boost to the car because the injectors were maxed out. They were releasing as much fuel as they could safely do on these standard fuel injectors. The standard fuel pump was also at full capacity.

It was delivering as much fuel as it could to the car. So, we found the limits of that fuel system.

VMAX —2021 — Upgrade the fuel system!

So, this is the next stage of this project — upgrade the fuel system.

The car is back in the workshop and we’re upgrading the fuel system.

We have developed our own upgraded fuel system for these Audi R8s and Huracáns here at Auto Torque. They’re upgraded fuel pumps — twin fuel pumps — as well as bigger injectors: 1650cc InjectorDynamic injectors.

These upgraded injectors along with the fuel pumps will allow more fuel to be dissipated into the engine, allowing us to up the boost further to drive more air through the turbos and thereby get bigger torque gains throughout.

We’re currently awaiting parts.

E85 ethanol fuel

This system will allow us to run E85 ethanol fuel in the tanks which is 85% ethanol and 15% road fuel.

We’ll be installing something called a Flex Fuel System. We put a sensor inline with the fuel system and that senses how much ethanol content goes through so that we could, theoretically, run anything from 100% ethanol to 0% ethanol which makes it a lot more practical to use the vehicle on the road.

With such a Flex Fuel System in place you would be able to use fuel from the pump with 99 RON fuel and then, if you want to go to the race track you can put pure ethanol in it. This allows for versatility in the vehicle, allowing it to be used both as a racetrack vehicle and a road vehicle.

The beauty of ethanol is that it just produces so much more horsepower. We expect to take that 850 WHP up over 1,000 WHP after this modification, perhaps even as much as 1,200 BHP, which is monstrous.

That will bring us to the limits of the stock engine and stock transmission

We’ll have the car on the hub dyno in December and hopefully will have some videos and pictures to show you then.

So, do you want one like this as well? Sure, bring your car down to the shop and we’ll set it all up for you with the greatest of pleasure.

March 2021 – Upgraded flex fuel system for E98 and dyno time.

Over the winter we decided it was a good opportunity to upgrade the AT850 package into the fire breathing AT1200 it deserved.

As mentioned above it was all about the fuel system for this next stage, because we had maxed the stock injectors and fuel pumps it was time to increase the capacity and introduce Ethanol E98!

Our full flex fuel system consists of

Flex fuel sensor

Serge tank

Dual fuel pumps

Modified secondary injector fuel rail

1750 Image Dynamic injectors

Fuel line kit and sensors

After installing the AT upgrade flex fuel system it was time to hit the dyno and calibrate the map for both ethanol and pump fuel. Romain at Race Cal was the man to call upon due to his vast experience with the Syvecs ecu and his knowledge on mapping flex-fuel systems, plus his state of the are hub dyno meant we would have no issues with traction or wheel slip.

Check out our short vidoe on the R8 below:

We were also approached by Jamie at Officially Gassed to review the car, check out his reaction below!